Case Study

Great Western Malting

Complete control system design and programming for a new malting facility on an aggressive 18-month fast-track schedule.

Client

Great Western Malting

Location

Pocatello, ID

Industry

Industrial

Completion

0

Project Overview

The Challenge

Industrial Systems has worked with Great Western Malting on various projects for over 20 years. GWM contacted us to assist with the design and construction of a new malting facility at their Pocatello, Idaho, site. This was a fast-track project that needed to be in production within 18 months of initial involvement, and concrete was already being poured by the time work began.

Our Approach

The Solution

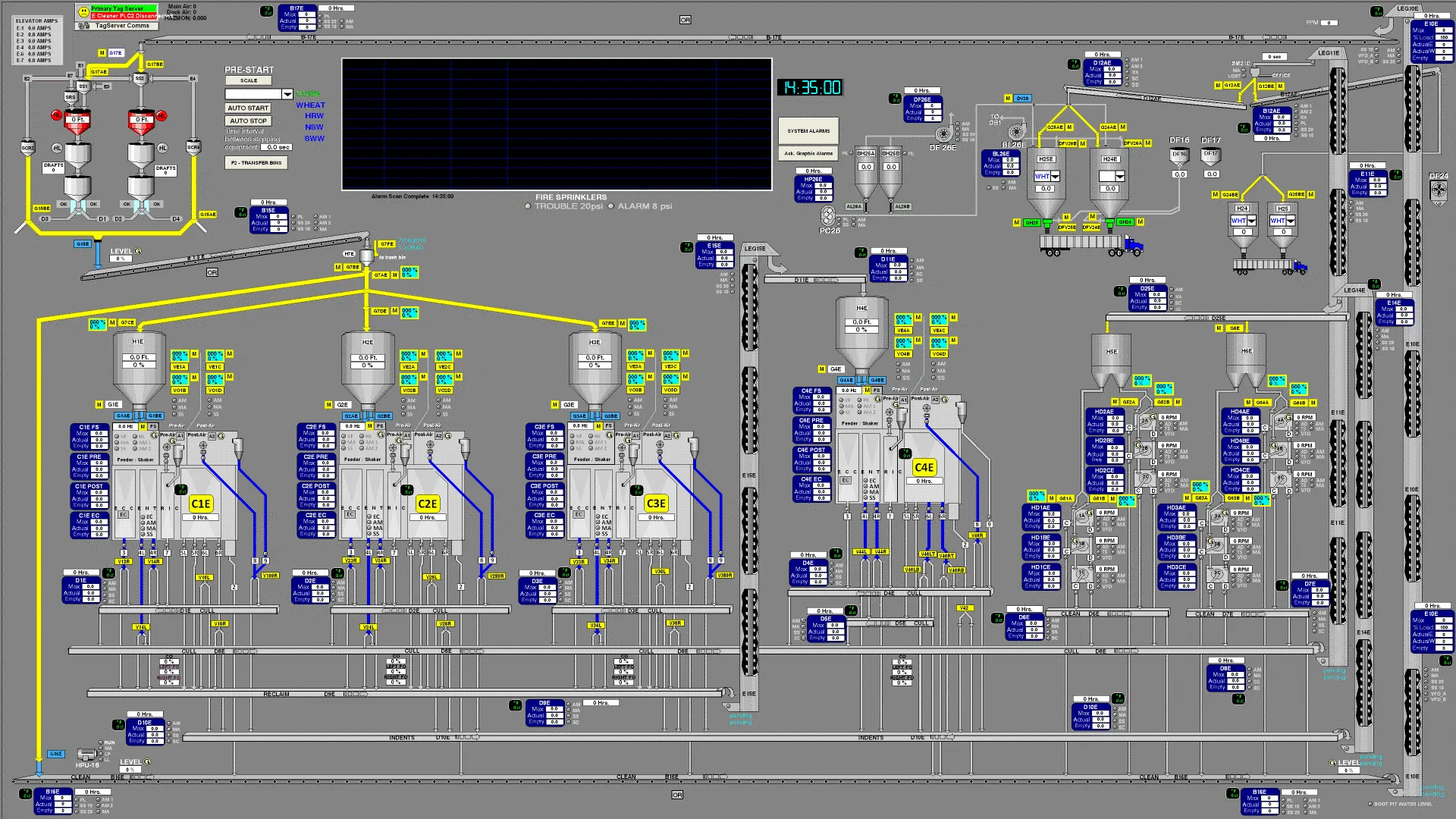

Design efforts focused on staying ahead of the contractors and the concrete for many months before shifting focus to final control system design and programming. A multi-level fiber network was designed to ring the site and provide separate physical network layers for SCADA, peer-to-peer, PLC I/O, and VFD communication needs.

All motor-driven equipment in the facility — including pumps, fans, and conveyors — is equipped with VFDs to provide maximum flexibility in production. The control system backbone is the latest 1 GB Ethernet-capable PLC processor from Allen-Bradley.

Results

Project Outcomes

The completed system uses a single Allen-Bradley processor to control 100 VFDs and nearly 2,000 I/O points, all over EtherNet/IP. The multi-level fiber network provides reliable, segmented communication across the entire facility.

100 variable frequency drives

VFDs

Nearly 2,000 points over EtherNet/IP

I/O Points

Delivered within 18-month fast-track schedule

Timeline

Project Team

Team Members

The people behind this project.

Work With Us

Ready to Discuss Your Project?

27+ years of delivering reliable SCADA solutions for critical infrastructure.

Related Work

More Industrial Projects

Explore similar case studies.

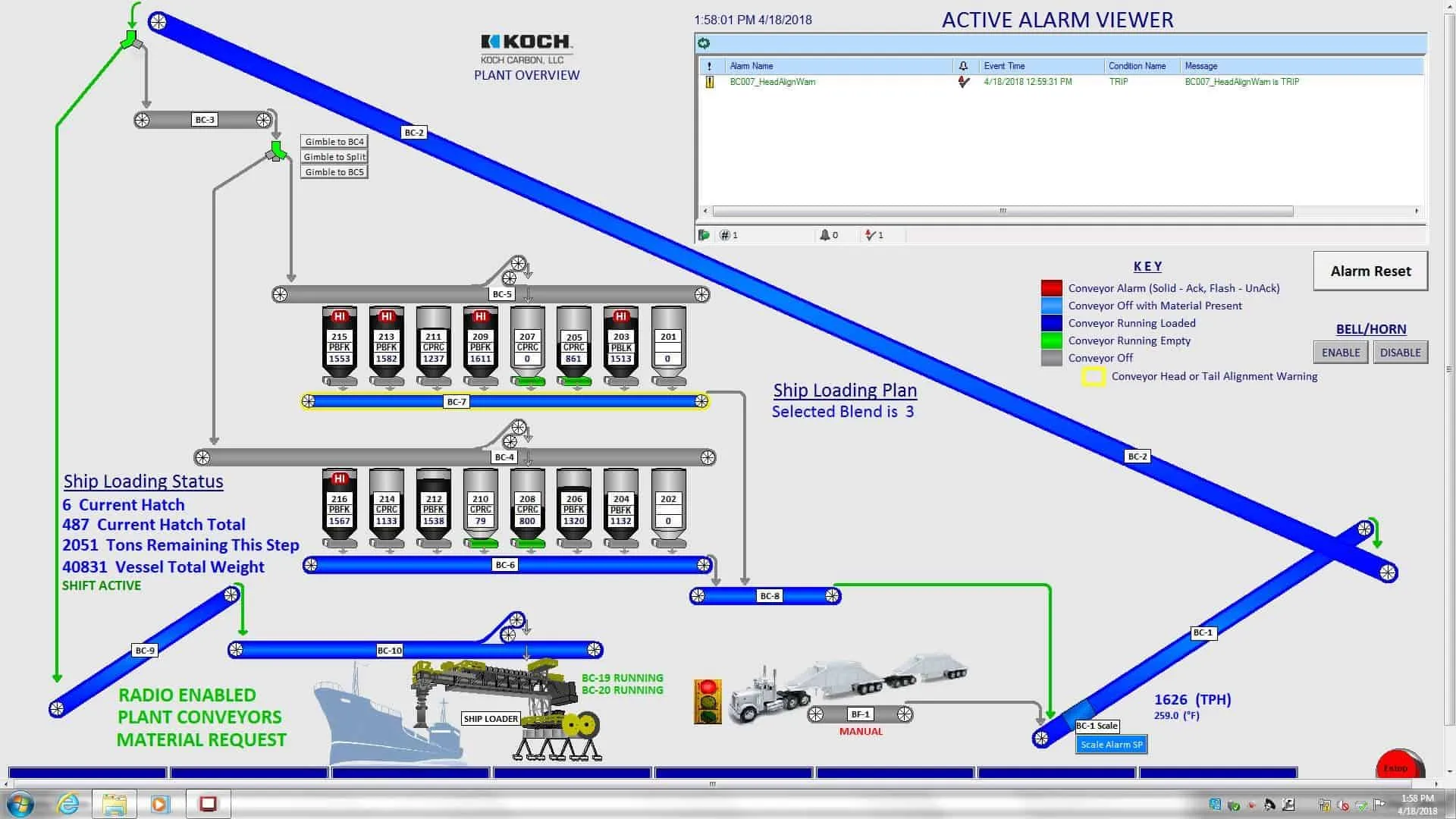

Columbia Export Terminal

SCADA expansion and plant-wide hazard monitoring for one of the Northwest's most automated grain export facilities — 22,000+ tags, 1,728 thermocouples, and redundant Wonderware servers.

Longbeach Export Terminal

Full PLC and HMI replacement at a bulk handling export terminal loading 50+ vessels per year — completed with zero planned downtime using a side-by-side migration approach.

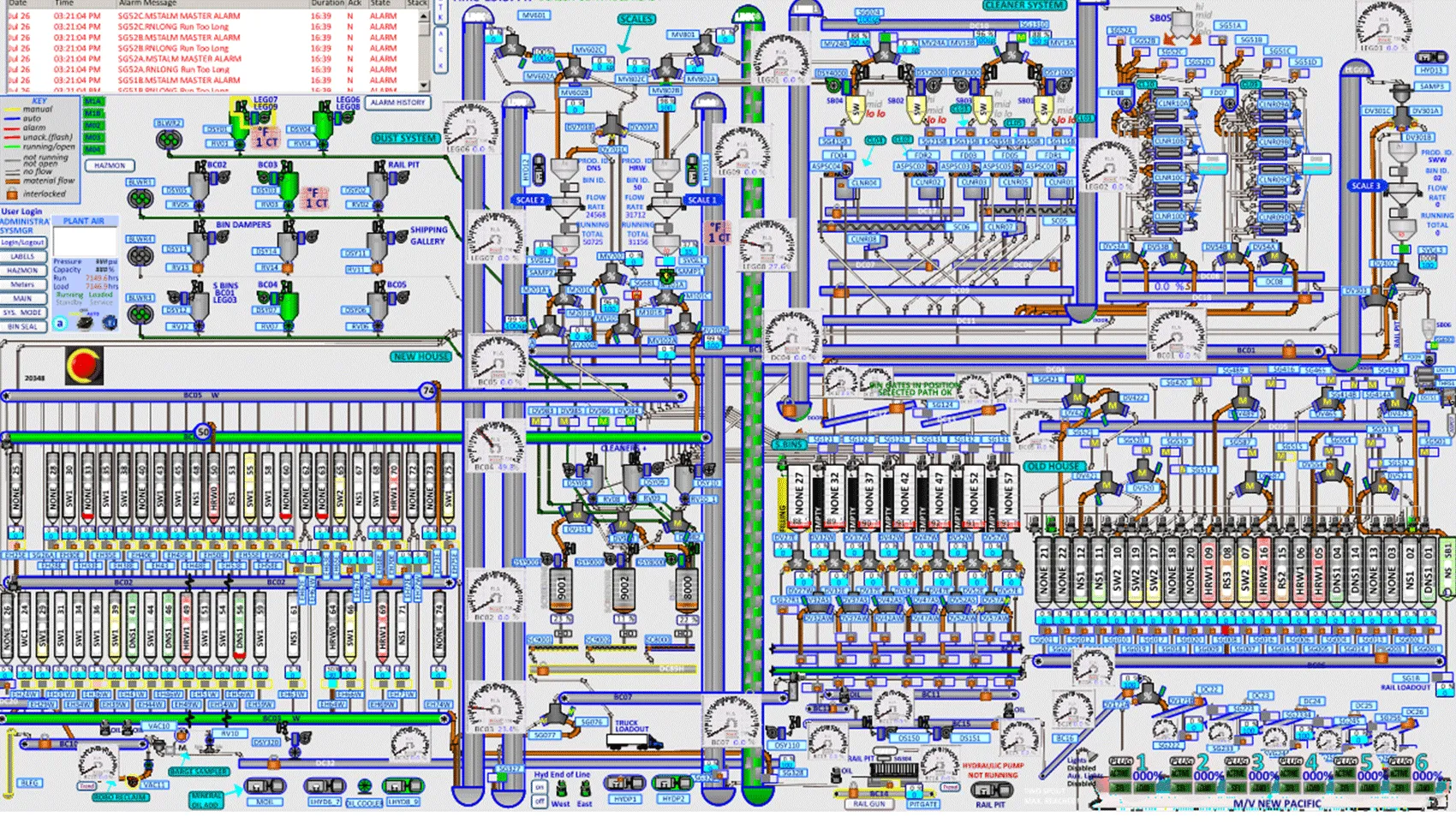

Louis Dreyfus Commodities (LDC)

Complete SCADA system design for a rebuilt grain facility — 20,000+ points, 1,000+ graphic objects, 6,000+ alarms, and integration with SQL inventory tracking.