Case Study

Longbeach Export Terminal

Seamless control system migration at a high-throughput bulk handling terminal with zero planned downtime.

Client

Koch Minerals / Longbeach Export Terminal

Location

Long Beach, CA

Industry

Industrial

Completion

0

Project Overview

The Challenge

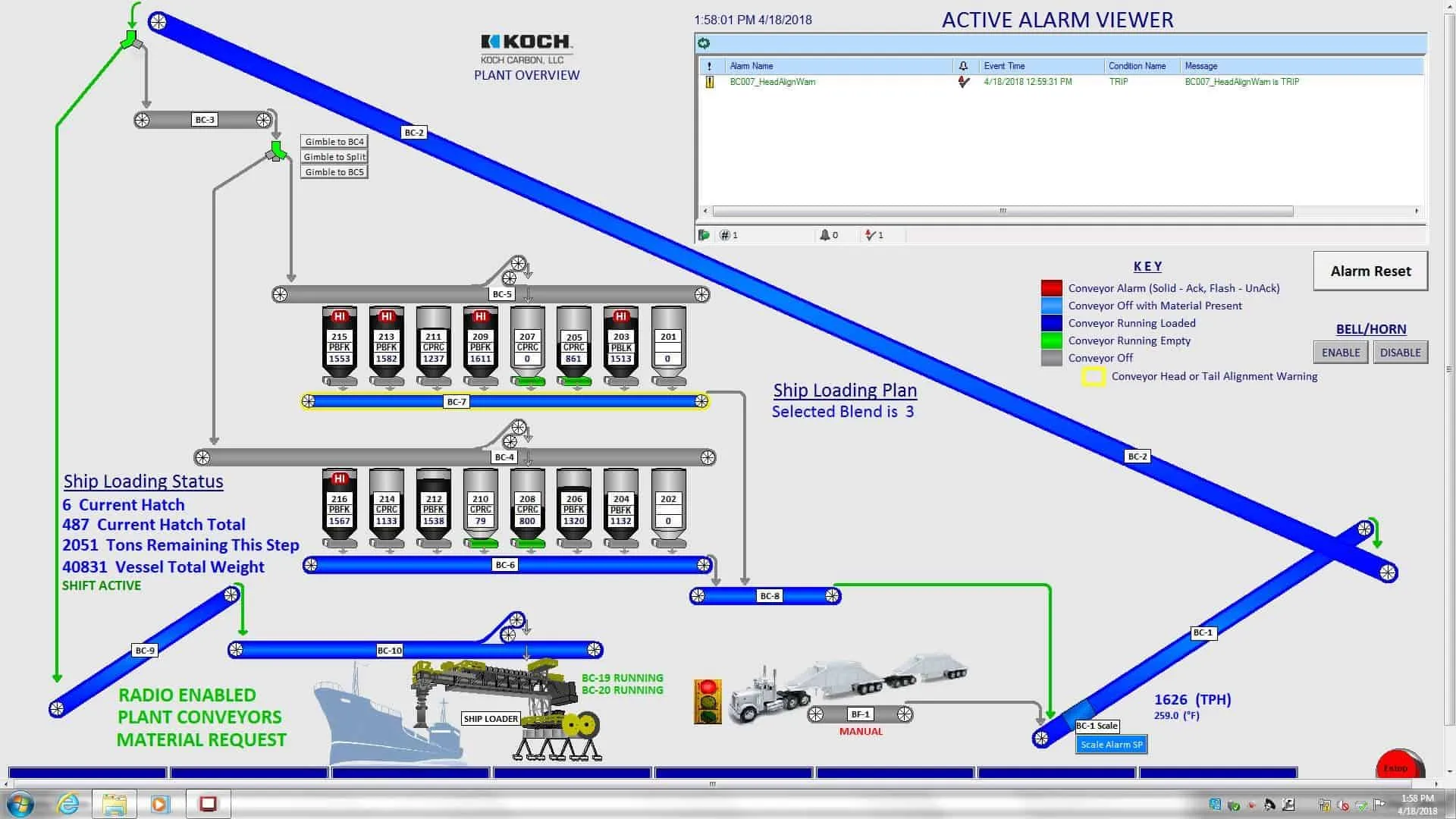

Koch Mineral's bulk handling facility at the Port of Long Beach receives material via truck, stores it in silos, and loads it onto vessels via a shiploader using a series of conveyor belts and belt feeders. At the time of the project, the terminal was loading approximately 50 vessels per year. Extended downtime due to a system failure would have been very costly in terms of dollars and the ability to meet customer commitments.

The old system had run for over 25 years, largely untouched, utilizing Allen-Bradley PLC-5 hardware and a custom-made graphical interface system. The graphics would often freeze and cause delays in operation. Many control and monitoring functions either did not work or were inaccurate. After a site evaluation, it was agreed upon that the best path forward would be to replace the PLC and HMI system while still utilizing existing electrical equipment and instrumentation.

Our Approach

The Solution

Allen-Bradley ControlLogix was selected for the PLC hardware and FactoryTalk View Site Edition for the HMI system. A fiber optic network was installed across the plant to interconnect remote PLCs and HMIs. The general approach to operating the plant was maintained but modified to be more intuitive for operators and to include additional monitoring, inventory tracking, alarming, and reporting. Remote access to the control system was also installed to allow the facility faster and less expensive support.

Rather than relying on a window of shutdown time, the new control system was installed side by side with the existing one. Periodically there would be a day or two where the facility did not need to run — this is when parallel wiring between the systems was installed. Field equipment, wiring, and programming were all tested and monitored well before the new system assumed control. Operators were also trained ahead of time.

Results

Project Outcomes

This approach allowed all the unknowns to be flushed out while the facility was still running. The old system was powered off when the facility had a two-day break in operations. The transition between control systems ended up being seamless and did not require a planned shutdown.

Zero planned downtime during migration

Downtime

25+ year PLC-5 system replaced

Legacy System

~50 vessels/year loading capacity maintained

Throughput

Project Team

Team Members

The people behind this project.

Work With Us

Ready to Discuss Your Project?

27+ years of delivering reliable SCADA solutions for critical infrastructure.

Related Work

More Industrial Projects

Explore similar case studies.

Columbia Export Terminal

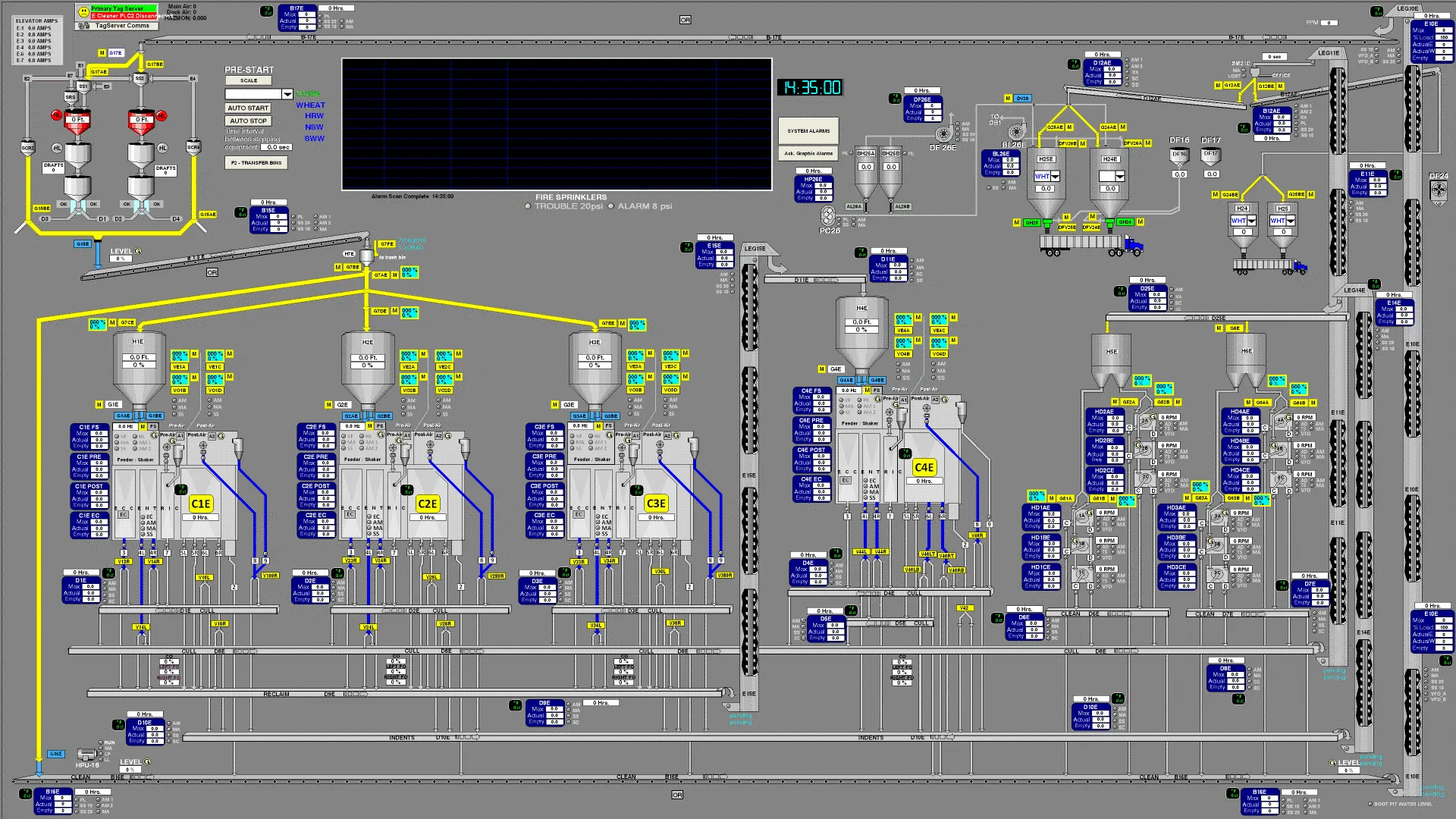

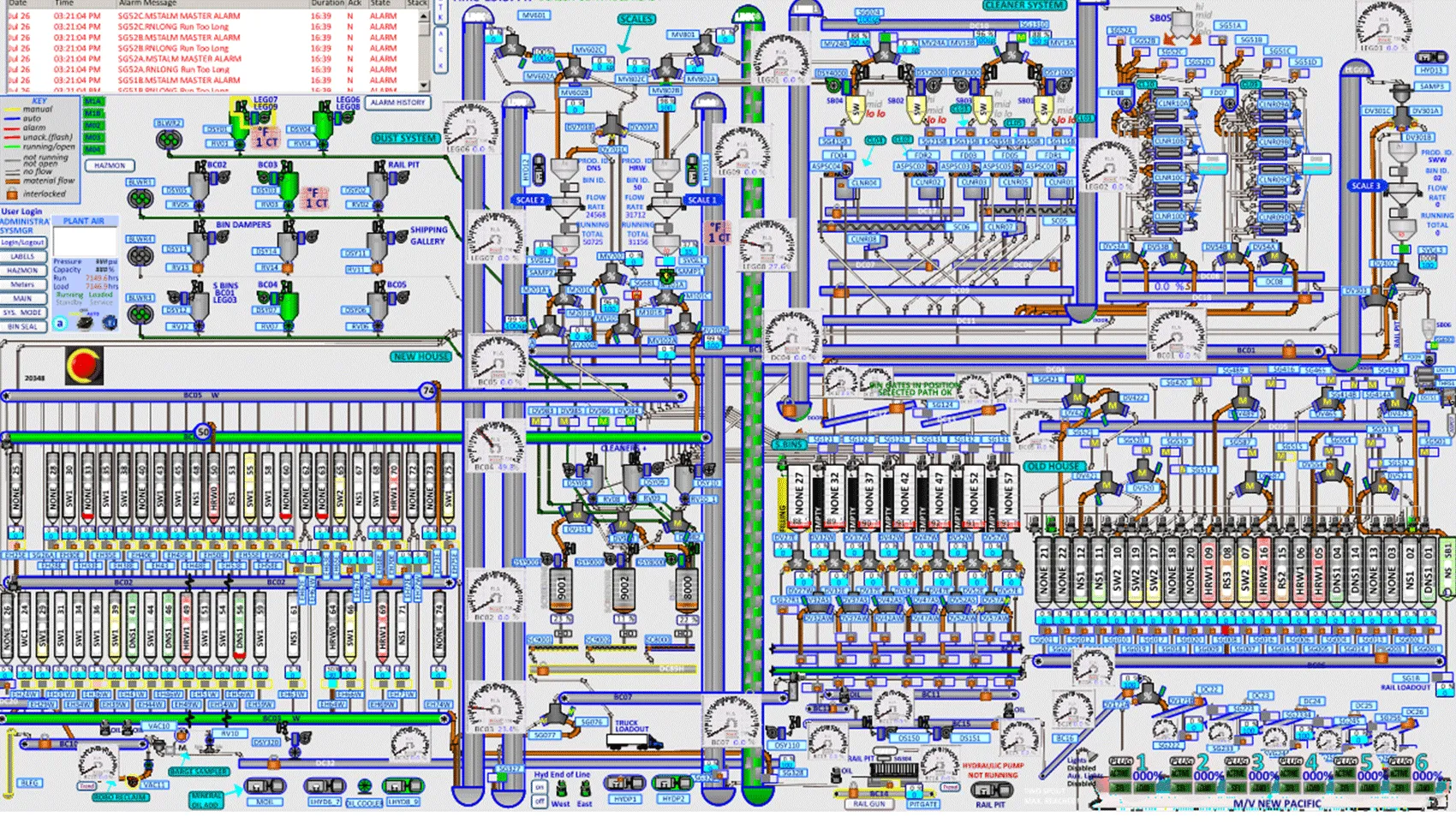

SCADA expansion and plant-wide hazard monitoring for one of the Northwest's most automated grain export facilities — 22,000+ tags, 1,728 thermocouples, and redundant Wonderware servers.

Great Western Malting

Fast-track control system design for a new malting facility — 100 VFDs, nearly 2,000 I/O points, and a multi-level fiber network delivered within an 18-month construction schedule.

Louis Dreyfus Commodities (LDC)

Complete SCADA system design for a rebuilt grain facility — 20,000+ points, 1,000+ graphic objects, 6,000+ alarms, and integration with SQL inventory tracking.