Case Study

Louis Dreyfus Commodities (LDC)

Full SCADA system design and programming for a ground-up grain facility rebuild with SQL inventory integration.

Client

Louis Dreyfus Commodities (LDC)

Location

Portland, OR

Industry

Industrial

Completion

0

Project Overview

The Challenge

LDC chose to rebuild their facility while retaining only a small amount of the original equipment. This meant replacing all the PLC hardware and installing a new SCADA system. R&W Engineering designed the plant electrical and programmed the PLC hardware. Industrial Systems was contracted to design and program the SCADA system.

Our Approach

The Solution

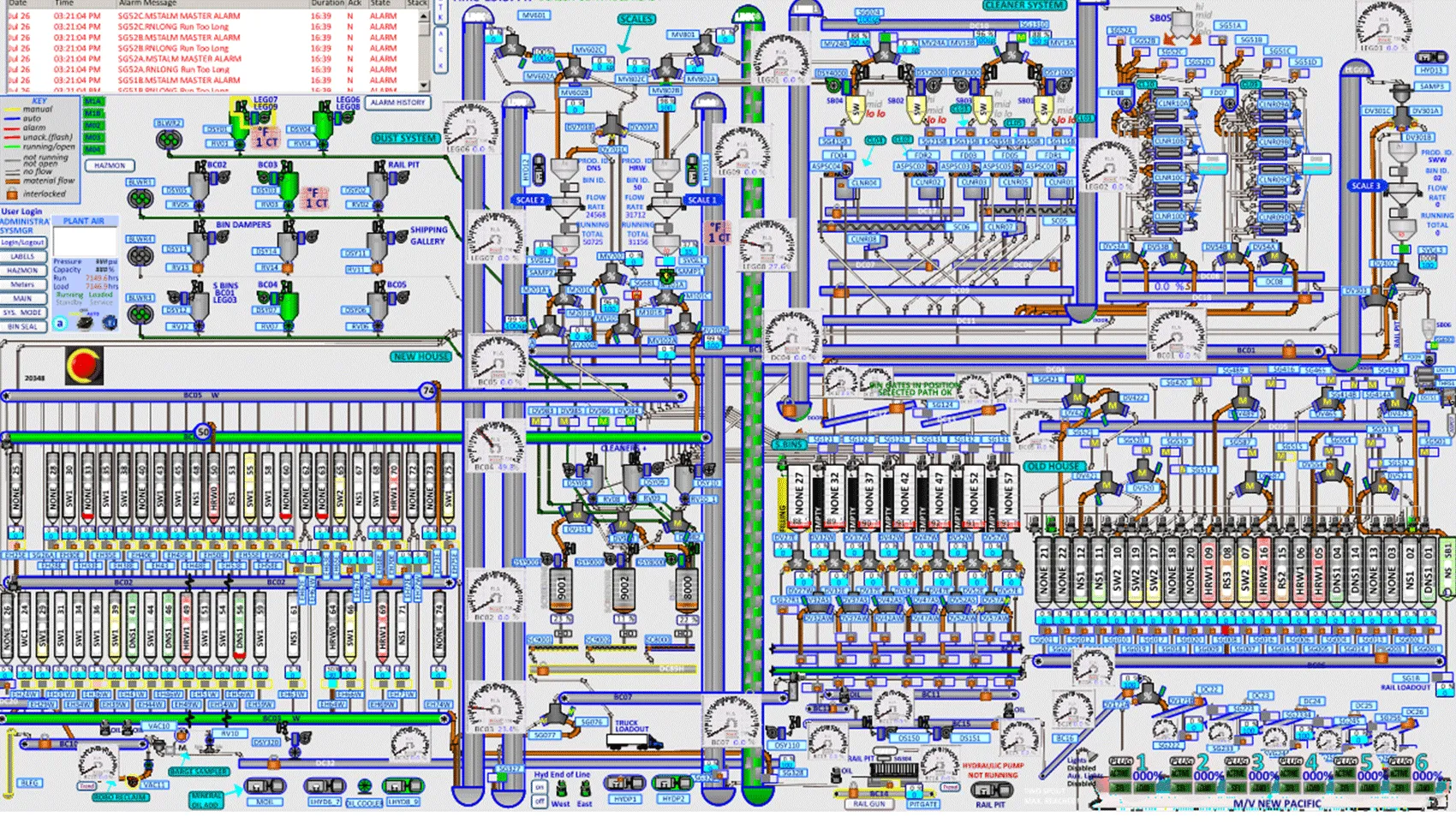

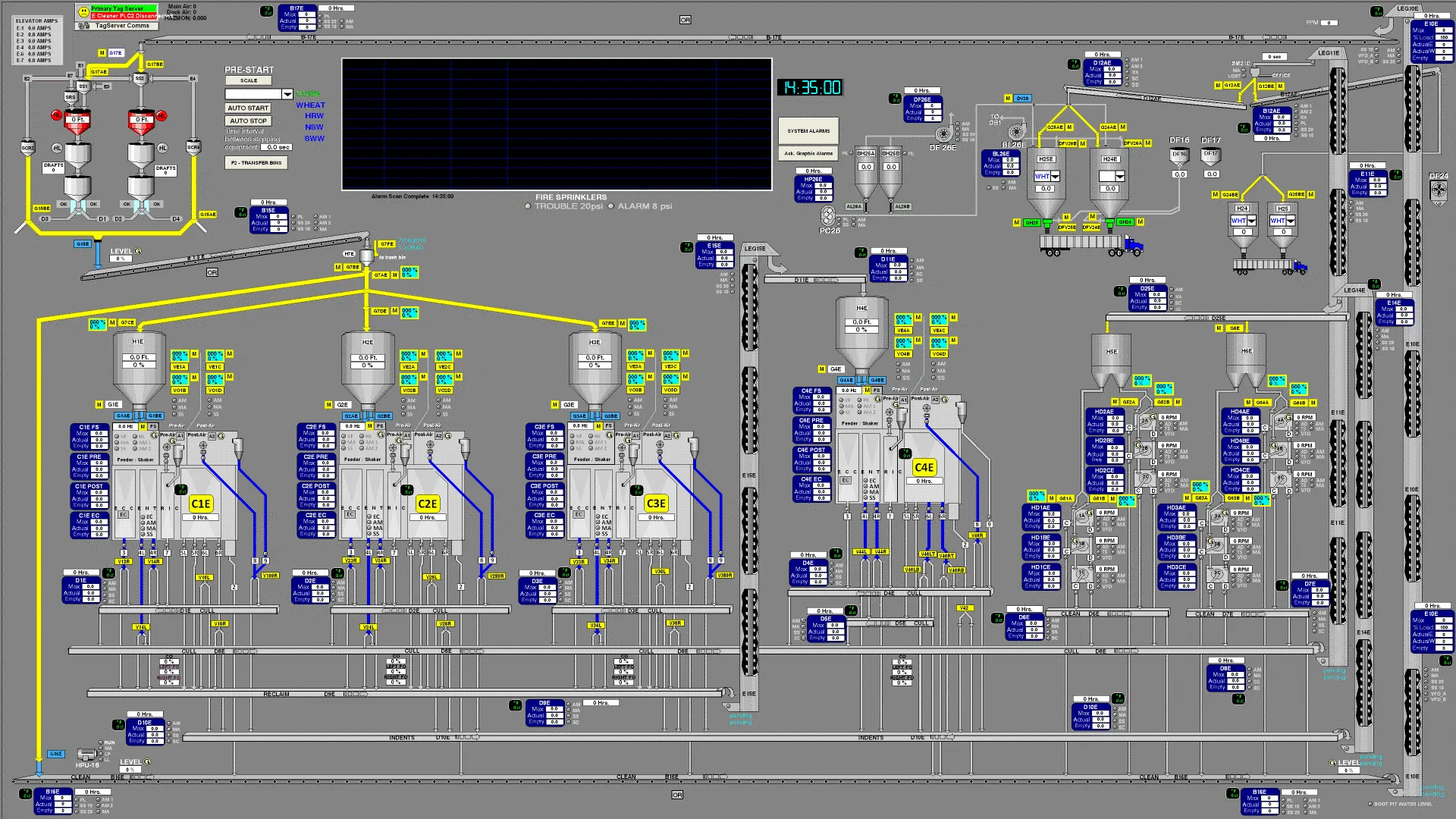

The SCADA integration included eight PLCs, a compressor, and three weigh scales communicating over Ethernet using a mix of hardwire and fiber optics. Equipment such as belts, drags, legs, and dust systems are wired to the PLC that is local to that area. Hazard temperature monitoring of bearings, rubs, and ambient temperatures are wired to multiplexers communicating to a single PLC via Ethernet. The SCADA system is also integrated into a separate plant SQL inventory system to display inventory levels, grades, and status of production.

SCADA PC integration includes a server, three 42-inch operational viewers, one 21-inch desktop viewer, one 21-inch Federal Grain Inspection viewer, and four concurrent user licenses for complete web page access to any operational graphic from any desktop on the plant intranet. SQL Server is used to track all equipment operation and temperature values.

Results

Project Outcomes

The completed SCADA system includes 20,000+ points, 1,000+ graphic objects, 44 types of equipment, and over 6,000 alarms. The graphic objects are designed with the future in mind — any changes needed to equipment can be made in one place so that modifying or adding equipment is quick, consistent with all other equipment, and without loss of production time.

20,000+ data points

SCADA Points

6,000+ configured alarms

Alarms

1,000+ reusable objects across 44 equipment types

Graphic Objects

Project Team

Team Members

The people behind this project.

Work With Us

Ready to Discuss Your Project?

27+ years of delivering reliable SCADA solutions for critical infrastructure.

Related Work

More Industrial Projects

Explore similar case studies.

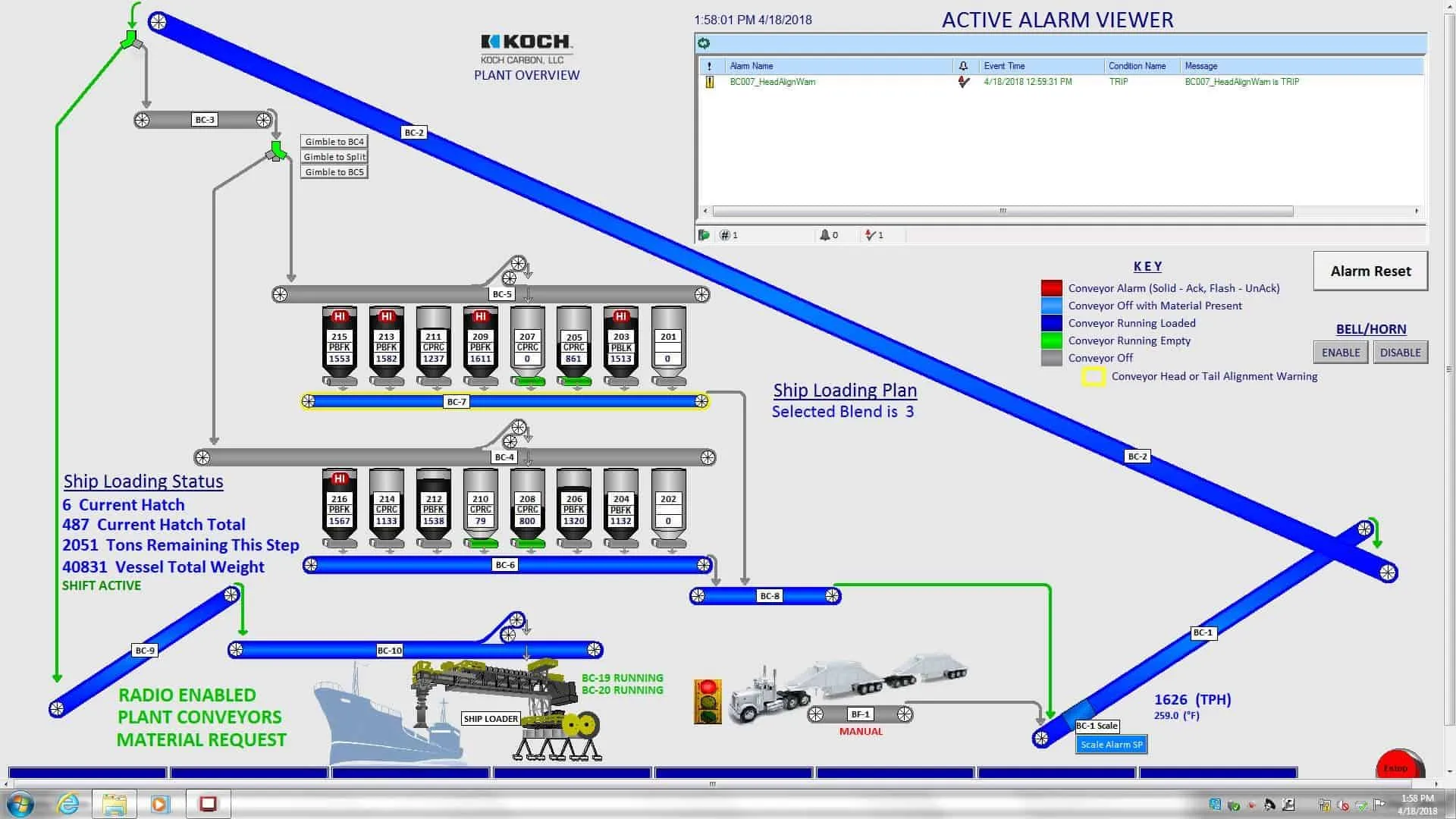

Columbia Export Terminal

SCADA expansion and plant-wide hazard monitoring for one of the Northwest's most automated grain export facilities — 22,000+ tags, 1,728 thermocouples, and redundant Wonderware servers.

Great Western Malting

Fast-track control system design for a new malting facility — 100 VFDs, nearly 2,000 I/O points, and a multi-level fiber network delivered within an 18-month construction schedule.

Longbeach Export Terminal

Full PLC and HMI replacement at a bulk handling export terminal loading 50+ vessels per year — completed with zero planned downtime using a side-by-side migration approach.