Case Study

Columbia Export Terminal

SCADA expansion and hazard monitoring upgrade for a highly automated grain export terminal.

Client

Columbia Export Terminal

Location

Portland, OR

Industry

Industrial

Completion

0

Project Overview

The Challenge

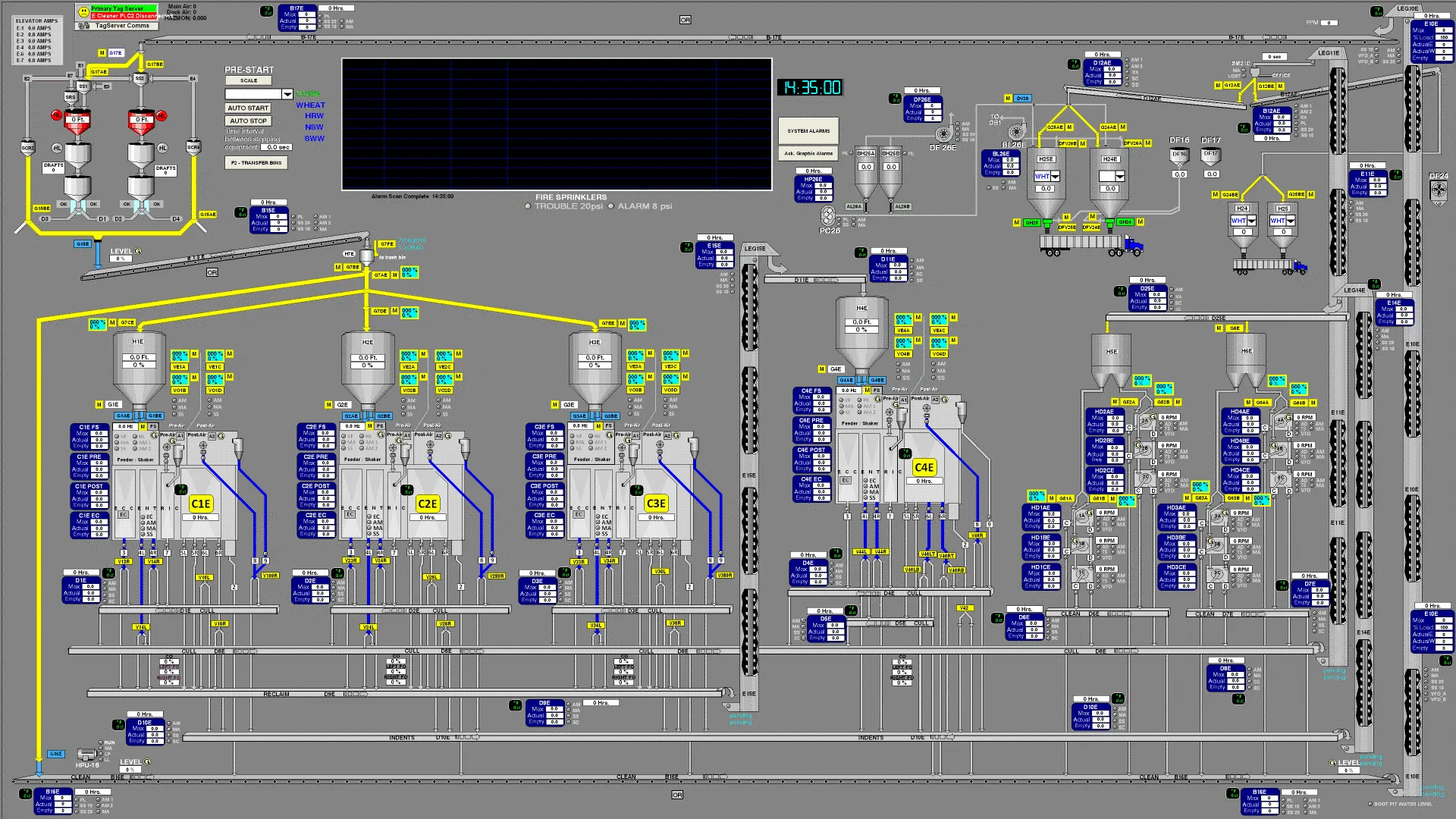

Columbia Export Terminal, located in Portland, OR, is one of the most automated and integrated grain export facilities in the Northwest. The terminal required SCADA additions for an expansion of their cleaning and storage capacity, as well as an update of their plant-wide hazard monitoring system.

Our Approach

The Solution

Industrial Systems provided the PLC and Wonderware programming for the SCADA expansion and hazard monitoring update. The I/O multiplexers installed can handle a total of 1,728 thermocouples, which monitor bearing and conveyor rub-block temperatures for plant alarm notification.

The automation control system comprises multiple Modicon PLCs linked by a fiber network. All I/O is monitored by two redundant Wonderware tag servers that handle over 22,000 tags used by the graphic system. This data is displayed on multiple view stations located in the main control room.

Results

Project Outcomes

The expanded SCADA system provides comprehensive monitoring of the facility's cleaning, storage, and material handling operations with redundant tag servers ensuring system reliability. The hazard monitoring system tracks 1,728 thermocouple points across the entire plant for early detection of bearing and conveyor issues.

22,000+ tags on redundant servers

SCADA Tags

1,728 temperature monitoring points

Thermocouples

Project Team

Team Members

The people behind this project.

Work With Us

Ready to Discuss Your Project?

27+ years of delivering reliable SCADA solutions for critical infrastructure.

Related Work

More Industrial Projects

Explore similar case studies.

Great Western Malting

Fast-track control system design for a new malting facility — 100 VFDs, nearly 2,000 I/O points, and a multi-level fiber network delivered within an 18-month construction schedule.

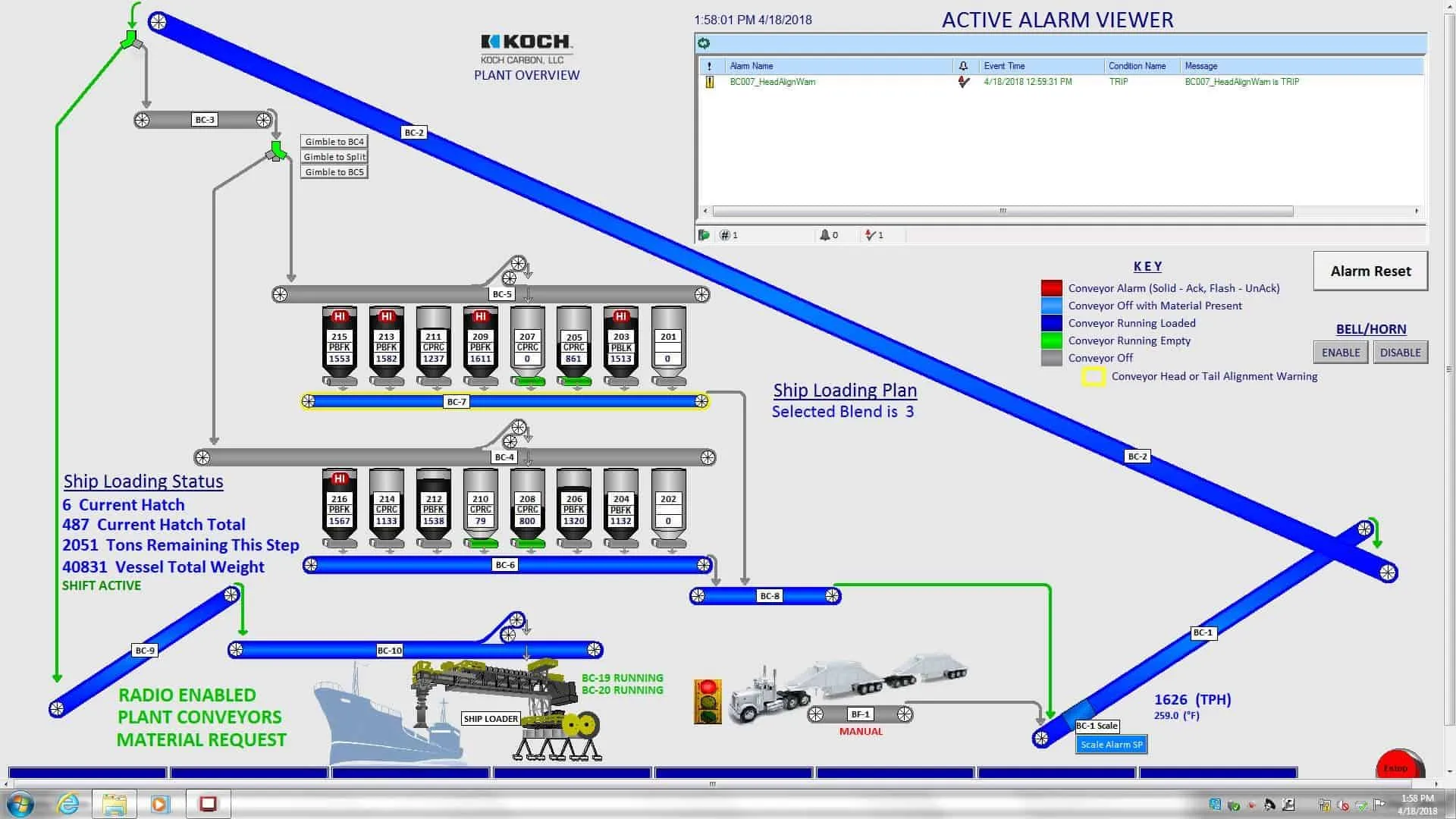

Longbeach Export Terminal

Full PLC and HMI replacement at a bulk handling export terminal loading 50+ vessels per year — completed with zero planned downtime using a side-by-side migration approach.

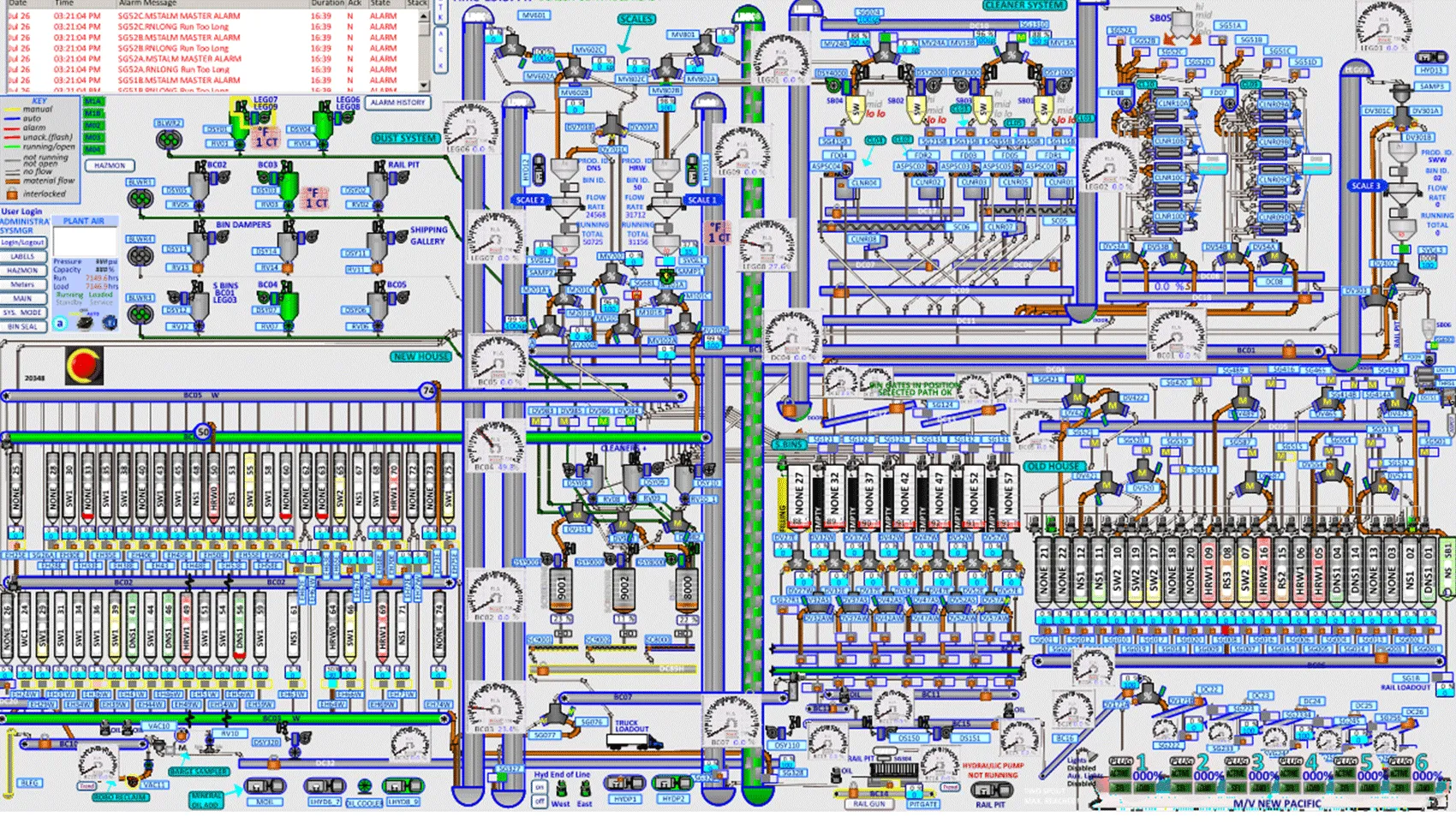

Louis Dreyfus Commodities (LDC)

Complete SCADA system design for a rebuilt grain facility — 20,000+ points, 1,000+ graphic objects, 6,000+ alarms, and integration with SQL inventory tracking.